Capacitor Discharge Spot Welder

Capacitor Discharge Spot Welding Machine

- Power Supply: 220V/380V, 50Hz

- Imput Power: 1.5~8 kVA

- Capacitance: 4050~49500 uF

- Energy Storage: 400~5000J

- Electrode Stroke: 30~60 mm

- Electrode Pressure: 1000~6000 N

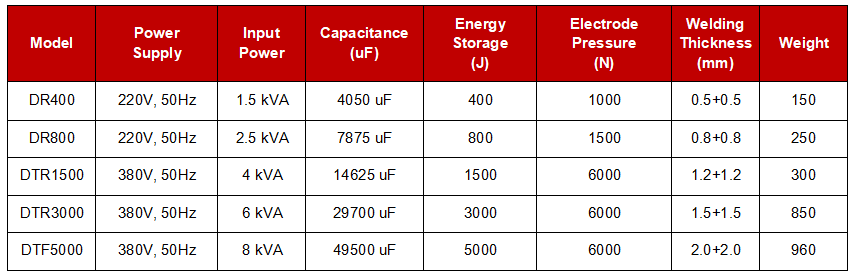

Technical Specification of Spot Welding Machine

Features of Capacitor Discharge Spot Welder

Timing and logic control based on high-performance 8-bit CPU.

Adopt 12-bit high-speed A/D conversion and real-time sampling of capacitor voltage.

The counting function is complete, and it can count the number of dots and the number of production.

Imported special capacitors for rapid charging and discharging are adopted, and the capacitor has a long life and stable capacity. The impact on the grid is small and the power factor is high.

The peak welding current is high, the time is short, and the specification is hard.

It is especially suitable for the welding of plates, wires and wires of metals with good electrical and thermal conductivity, such as aluminum and copper, and the precision welding of dissimilar metals.

Introduction of Capacitor Discharge Spot Welder

Capacitor energy storage welding machine is mainly composed of power rectifier part, charge and discharge conversion circuit, welding transformer, welding circuit, electrode pressure mechanism, etc. The principle of capacitor energy storage welding is to use the energy slowly stored in the capacitor from the power grid. In a short period of time, the metal is heated and melted by discharging the welded workpiece through the resistance welding transformer. Compared with other welding methods such as AC machines, the instantaneous power drawn from the power grid is low, the load of each phase is balanced, the power factor is high, and it can provide concentrated energy to the welding zone, and can obtain weldments with good surface quality and small deformation. Some hard-to-weld non-ferrous metals with good thermal and electrical conductivity. Suitable for welding aluminum, copper silver, nickel metal and alloy materials. This welding method has been widely used in industrial production, such as hardware, household appliances, electronics, metal utensils and other industries.

Introduction of Capacitor Discharge Spot Welder

The principle of the capacitor discharge spot projection welding machine is to charge and store a group of high-capacity capacitors through a small transformer in advance, and then discharge and weld the welding parts through a high-power welding resistance transformer. The outstanding features of the energy storage spot projection welding machine are short discharge time and large instantaneous current, so the thermal effects such as deformation and discoloration after welding are minimal. The low-power energy storage welding machine is suitable for welding precision parts, and the high-power energy storage welding machine is suitable for multi-point projection welding, ring projection welding, and sealing projection welding.

It can weld common ferrous metal steel, iron and stainless steel, copper, silver, nickel and other alloy materials, as well as welding between dissimilar metals. It can also weld high-strength steel, hot-formed steel spot welding and nut projection welding, with high welding strength and welding points. Beautiful

Send Message

Catalogue

News & Technicals

Structure of Nut Electrode of Intermediate Frequency Spot Welder

Analyze the Electrode of the Intermediate Frequency Spot Welder

Analyze the Influence of the Welding Point Distance of the Spot Welder

Function of Butt Welding Machine Inspection System

Contact Us

Email: info@resistancewelder.com

Tel: 0086-130-8387-7627

Factory:

102A, 1st Floor, Building 3, 51 Xiangshan Avenue, Ningxi Street, Zengcheng District, Guangzhou