Table Type Spot Welding Machine

DC Power Table Type Spot Welding Machine

- The use of intermediate frequency DC welding power supply is ideal for more precise and stable welding. It has the characteristics of an intermediate frequency DC welding machine. Unique electrode pressure mechanism, sensitive electrode pressure adjustment, high electrode followability, especially suitable for welding fine workpieces. The frame is made of aluminum profile, neat and beautiful.

Features of Invert Resistance Spot Welding Machine

The intermediate frequency inverter welding machine is a three-phase alternating current that is bridge rectified and filtered to obtain a relatively stable direct current. The 1000 Hz intermediate frequency alternating current is generated through the inverter, and then the resistance welding transformer is fed, and the resistance welding transformer secondary output low-voltage alternating current is single-phase full-wave rectified to produce direct current with a small amount of pulsation for welding.

The intermediate frequency welding power supply is a three-phase balanced load, which has a much smaller impact on the power grid than single-phase AC welding, which reduces the requirements of the power supply system. Because the primary input frequency of the resistance welding transformer is higher, the volume and weight of the transformer can be greatly reduced. It is only 1/4 to 1/3 of the AC transformer of the same power, the output welding current is DC, the power factor is as high as 90%, the thermal efficiency is high, the welding time is short, and the transformer power required under the same welding capacity is only AC About 1/2 of the transformer power, the energy saving effect is remarkable.

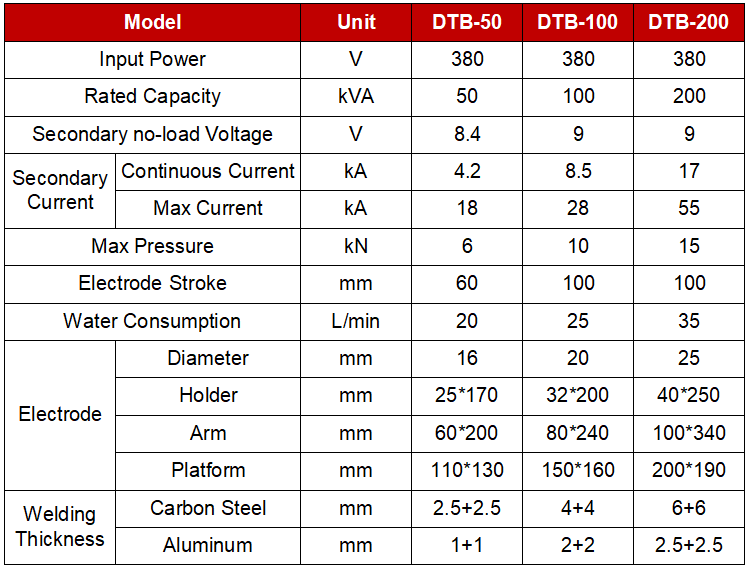

Technical Specification of Spot Welding Machine

| Model | Unit | DTB-50 | DTB-100 | DTB-200 | DTB-320 | |

| Input Power | V | 380 | 380 | 380 | 380 | |

| Rated Capacity | kVA | 50 | 100 | 200 | 320 | |

| Secondary no-load Voltage | V | 8.4 | 9 | 9 | 9 | |

| Secondary Current | Continuous Current | kA | 4.2 | 8.5 | 17 | 25.5 |

| Max Current | kA | 18 | 28 | 55 | 70 | |

| Max Pressure | kN | 6 | 10 | 15 | 24 | |

| Electrode Stroke | mm | 60 | 100 | 100 | 100 | |

| Water Consumption | L/min | 20 | 25 | 35 | 50 | |

| Electrode | Diameter | mm | 16 | 20 | 25 | 25 |

| Holder | mm | 25*170 | 32*200 | 40*250 | 40*250 | |

| Arm | mm | 60*200 | 80*240 | 100*340 | 100*340 | |

| Platform | mm | 110*130 | 150*160 | 200*190 | 200*190 | |

| Welding Thickness | Carbon Steel | mm | 2.5+2.5 | 4+4 | 6+6 | 5+5 |

| Aluminum | mm | 1+1 | 2+2 | 2.5+2.5 | 3.5+3.5 | |

Send Message

Catalogue

News & Technicals

Structure of Nut Electrode of Intermediate Frequency Spot Welder

Analyze the Electrode of the Intermediate Frequency Spot Welder

Analyze the Influence of the Welding Point Distance of the Spot Welder

Function of Butt Welding Machine Inspection System

Contact Us

Email: info@resistancewelder.com

Tel: 0086-130-8387-7627

Factory:

102A, 1st Floor, Building 3, 51 Xiangshan Avenue, Ningxi Street, Zengcheng District, Guangzhou