Precise Spot Welding Machine

Medium Frequency Precise Spot Welder

- Equipped with new generation microcomputer controller, the current is accurate and stable, and it is widely used in the welding of copper wire connectors, silver contacts, bimetallic pieces and small hardware, and fine workpieces of electrical switches.

- The water pipe is equipped with quick connectors to facilitate the replacement of water-cooled electrodes or fixtures.

Features of Precise Spot Welding Machine

The precision desktop spot welding machine produced by our company is compact in structure, saving space, low current, more precise in control, and economical.

Vertical pressure mechanism, the guide part adopts linear guide, high followability;

High-strength body structure, good rigidity, can prevent the electrode tip from sliding when pressurized;

Safe, high-performance pneumatic system. The electrode pressure speed can be adjusted at will.

The waterway is equipped with quick-connect connectors to facilitate the replacement of water-cooled electrodes or fixtures;

Equipped with a new generation of microcomputer controller, the current is accurate and stable, with constant current and constant voltage functions. The constant current accuracy can reach ±2% in ICYC. There are 31 sets of programs for users to choose and use, and each specification can achieve dots. , The counting function of production number and accumulative counting can also use the electrode head method to count the line. The operation panel adopts a numeric keyboard, which can realize accurate parameter setting. The welding program has a multi-pulse mode, and the current and time of the preheating, welding, tempering and other programs can be selected and displayed, which is convenient for the user to adjust and select the specifications. Some common faults can be self-diagnosed and classified and displayed, which is convenient for users to troubleshoot and maintain.

Application of Table Type Precise Spot Welder

It is especially suitable for welding fine workpieces such as electrical switches, copper wire connectors, terminal wires, silver contacts, chip inductors, coils, fuses, and small hardware. It is widely used for welding precision components such as electronics, electrical appliances, medical equipment, instruments and meters.

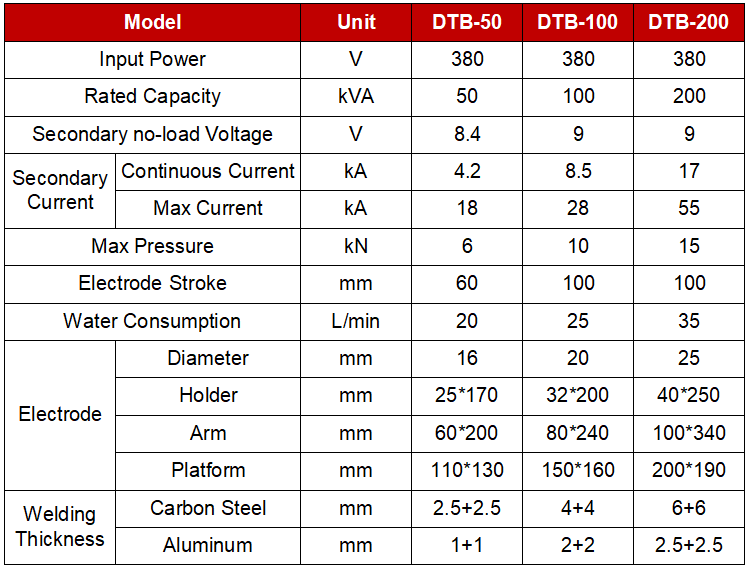

Technical Specification of Precise Spot Welding Machine

| Model | Unit | DTB-50 | DTB-100 | DTB-200 | DTB-320 | |

| Input Power | V | 380 | 380 | 380 | 380 | |

| Rated Capacity | kVA | 50 | 100 | 200 | 320 | |

| Secondary no-load Voltage | V | 8.4 | 9 | 9 | 9 | |

| Secondary Current | Continuous Current | kA | 4.2 | 8.5 | 17 | 25.5 |

| Max Current | kA | 18 | 28 | 55 | 70 | |

| Max Pressure | kN | 6 | 10 | 15 | 24 | |

| Electrode Stroke | mm | 60 | 100 | 100 | 100 | |

| Water Consumption | L/min | 20 | 25 | 35 | 50 | |

| Electrode | Diameter | mm | 16 | 20 | 25 | 25 |

| Holder | mm | 25*170 | 32*200 | 40*250 | 40*250 | |

| Arm | mm | 60*200 | 80*240 | 100*340 | 100*340 | |

| Platform | mm | 110*130 | 150*160 | 200*190 | 200*190 | |

| Welding Thickness | Carbon Steel | mm | 2.5+2.5 | 4+4 | 6+6 | 5+5 |

| Aluminum | mm | 1+1 | 2+2 | 2.5+2.5 | 3.5+3.5 | |

Send Message

Catalogue

News & Technicals

Structure of Nut Electrode of Intermediate Frequency Spot Welder

Analyze the Electrode of the Intermediate Frequency Spot Welder

Analyze the Influence of the Welding Point Distance of the Spot Welder

Function of Butt Welding Machine Inspection System

Contact Us

Email: info@resistancewelder.com

Tel: 0086-130-8387-7627

Factory:

102A, 1st Floor, Building 3, 51 Xiangshan Avenue, Ningxi Street, Zengcheng District, Guangzhou